What is Silo Maxx?

Our inoculants provide superior protection over longer periods of time with specially-selected bacteria that work even better together, over longer periods of time, with added boosts of enzymes to make operations that much more efficient.

Formulated with PEAK Forage Solutions, inc. proprietary combination of bacteria, enzymes, antioxidants, and potassium sorbate, Silo Maxx can be used for the treatment of:

- Legume Silages

- Grass Silages

- Balage

- Corn Silage

- Earlage

- Dry Hay

| Silo Maxx Products | Hay | Balage | Legume Silage | Grass Silage | Sorghum Sudan | Forage Sorghum | Small Grain Silage | Corn Silage | HM Corn | Avail Online |

|---|---|---|---|---|---|---|---|---|---|---|

| Silo Maxx 25# Bag | YES | YES | YES | YES | YES | YES | YES | YES | YES | YES |

| Silo Maxx Special 25# Bag | YES | YES | YES | YES | YES | YES | YES | YES | YES | YES |

| Silo Maxx WS 50T | NO | YES | YES | YES | YES | YES | YES | YES | YES | YES |

| Silo Maxx WS 250T | NO | YES | YES | YES | YES | YES | YES | YES | YES | YES |

| Silo Maxx WS 500T | NO | YES | YES | YES | YES | YES | YES | YES | YES | NO |

| Silo Maxx WS LO 500T | NO | YES | YES | YES | YES | YES | YES | YES | YES | YES |

Available as a dry granular or water soluble treatment product depending on producer's needs.

Dry version available for organic producers.

How is Silo Maxx Better?

Three key technologies make our inoculants protect better, boost feed efficiency, and last longer.

-

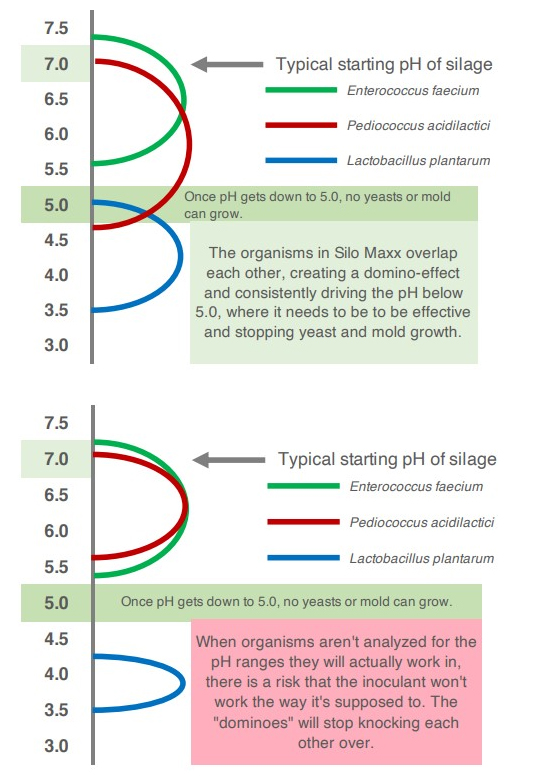

Specifically-selected bacteria that work together - Silage inoculants can’t work unless the acids produced by the bacteria drive the pH of the silage low enough to make sure that yeasts and molds can’t grow. However, the problem that some inoculants have is that the specific strains that are chosen don’t overlap each other in what’s called Floral Succession. You can think of Floral Succession as dominoes that knock each other over and allow the next one to fall. In an inoculants, the first organism to start working needs to drive the pH low enough to be in a range where the next organism can start to “come alive” and work... and so on. The bacteria used in Silo Maxx create the success that allows for each strain to work with the next.

The figure on top shows the action of the organisms chosen for Silo Maxx. The one below it shows what happens when the organisms chosen do not work well together.

Figure 1:

-

Added Enzymes Specifically Formulated to Boost Feed Efficiency - Some bacteria produce enzymes on their own that help to breakdown macronutrients like carbohydrates. With Silo Maxx, we’ve formulated it to include an additional enzyme boost to make this process even more efficient. So instead of using her energy to breakdown food, cows can use their energy to produce more milk.

-

Proprietary Technology that Lasts Longer - All of these technologies don’t matter much if the product doesn’t remain alive and viable for as long as possible. To make sure Silo Maxx lasts longer than others, we’ve included a proprietary technology in the way that the bacteria we use is grown and processed in order to remain stable over longer periods of time.

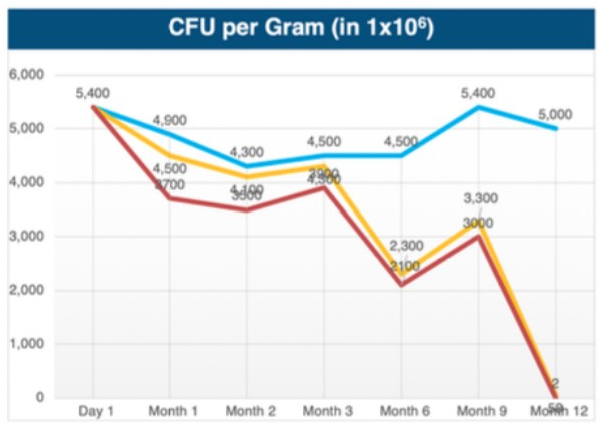

Our organisms underwent a 12-month study to show their stability compared to typical bacterial cultures on the market. What we found is that Peak’s Silo Maxx bacterial cultures and the proprietary technology used to grow them remained alive and viable for a much longer period than others.

The blue line shows that the number of bacteria that remained alive and viable after 1 year using our methods remained nearly the same. The yellow line shows a control group processed using typical inoculant organism processes and technology. Finally, the red line indicates the control group without any special measures taken to keep the bacteria stable.

As you can see, at around 3 months the controls’ bacteria begins to die off rapidly whereas an organism used in Silo Maxx remains stable at 1 year.

This trial was conducted using Enterococcus faecium under normal circumstances, keeping the bacterial cultures at room-temperature (70OF).

How it works:

Eliminating oxygen from a silo or bunker helps control spoilage organisms, but it is wise to include an antimicrobial agent to complete the job. While many silage inoculants use Lactobacillus buchneri to control spoilage organisms through the production of acetic acid, Peak Forage Solutions uses potassium sorbate, a common human food-grade preservative, for several reasons:

- Potassium sorbate is as effective as L. buchneri (Kleinschmit et. al., 2005, J. Dairy Sci., 2130 – 2139) (Da Silva et. al., 2014, ADSA/ASAS/CSAS abstracts, abstract 1078).

- Potassium sorbate starts to work immediately whereas, L. buchneri can take 60 days or more to produce acetic acid (Da Silva et. al., 2014, ADSA/ASAS/CSAS abstracts, abstract 1078; Kleinschmit and Kung, 2006, J. Dairy Sci., 3999 – 4004).

- Potassium sorbate does not have to compete with epiphytic microbes like L. buchneri must (Da Silva et. al., 2014, ADSA/ASAS/ CSAS abstracts, abstract 1078).

- Potassium sorbate does not depend on the production of acetic acid like L. buchneri. Carbon dioxide is produced in the production of acetic acid creating a loss of carbon (dry matter loss or shrink).